Hydrostatic testing, also known as hydro testing, is the process of testing gas cylinders for strength and leaks. This test is done on most types of cylinders like oxygen, argon, nitrogen, hydrogen, carbon dioxide, calibration gases, gas mixtures, and seamless or welded cylinders regardless of the cylinder material. Periodic hydro testing validates that the cylinder is in proper working condition and suitable for continued use for a specified period.

Hydro testing of cylinders is mandatory according to guidelines from the Petroleum and Explosives Safety Organization (PESO). High-pressure seamless cylinders must undergo periodic hydro testing every 5 years or as needed depending on the cylinder's condition. Some gas cylinders like CNG and toxic gases need more frequent testing, such as every 2 years.

During a hydro test, the cylinder is pressurized to a test pressure, usually 1.5 or 1.66 times the working pressure. This checks the material's elasticity, which deteriorates over time with repeated filling cycles. The cylinder is pressurized then depressurized to ensure it returns to its original dimensions within specified tolerance limits. Periodic hydro testing confirms the cylinder material still has adequate elasticity for safe continued use.

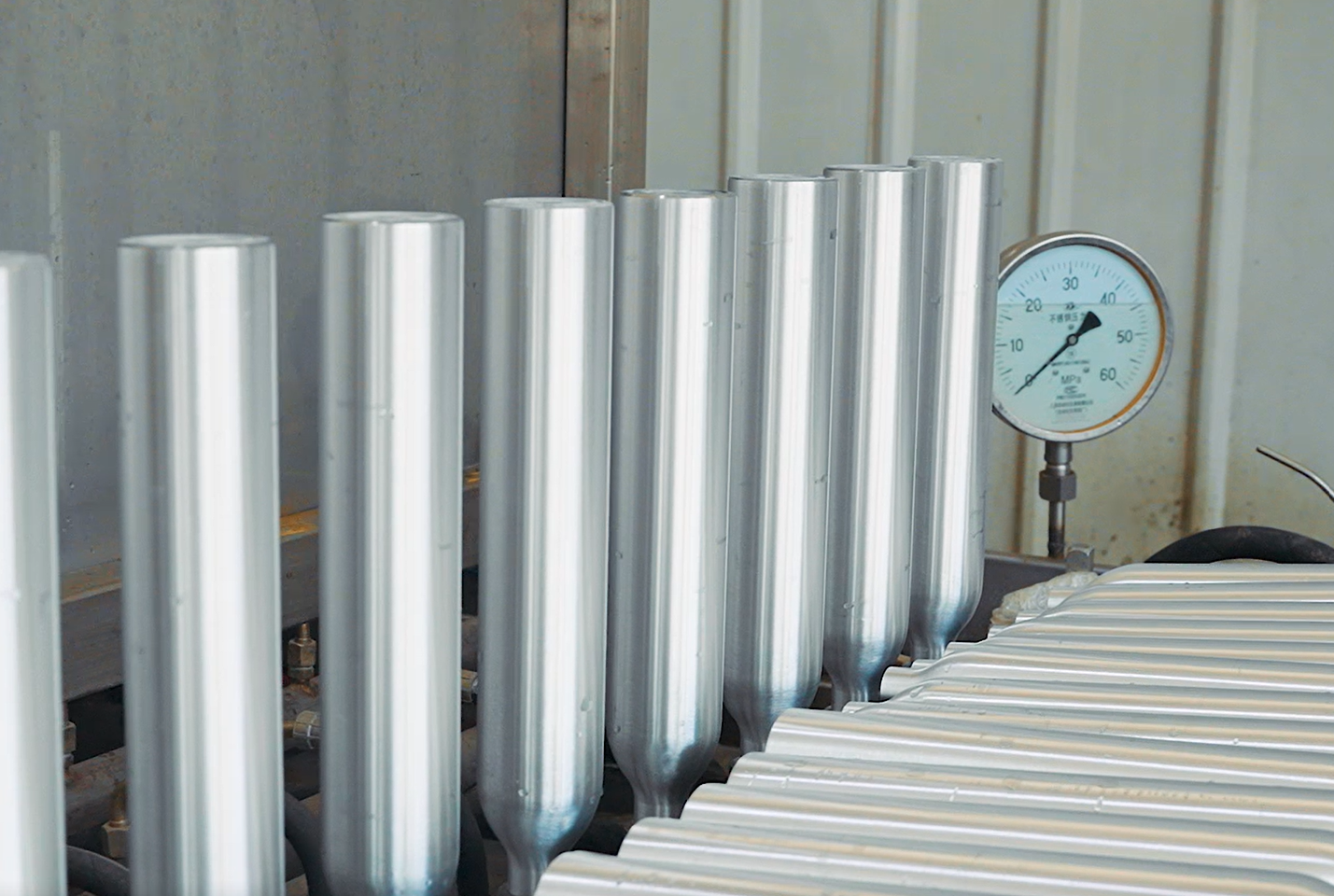

The hydro test procedure involves filling the cylinder with a nearly incompressible liquid, usually water, and examining it for leaks or permanent changes in shape. Water is commonly used as it is almost incompressible and will only expand by a very small amount. If high-pressure gas was used, the gas could expand up to several hundred times its compressed volume, running the risk of serious injury. The test pressure is always considerably more than the operating pressure to give a margin for safety. Typically, 150% of the operating pressure is used.

The cylinder is placed inside a water jacket that has a known volume. The water jacket is connected to a calibrated burette that measures the change in volume of the water inside the jacket. The cylinder is then pressurized with water until it reaches the test pressure. The pressure is held for a certain amount of time, usually 30 seconds or more. During this time, the cylinder expands slightly and displaces some water from the jacket to the burette. The amount of water displaced indicates the expansion of the cylinder under pressure. After the holding time, the pressure is released and the cylinder contracts to its original size. The water that was displaced returns to the jacket from the burette. The difference between the initial and final readings of the burette indicates the permanent expansion of the cylinder.

The permanent expansion must not exceed 10% of the total expansion. If it does, it means that the cylinder has lost some of its elasticity and may have developed cracks or flaws that compromise its integrity. Such cylinders must be removed from service and destroyed. The hydro test also checks for leaks by observing any drop in pressure during the holding time or any bubbles escaping from the cylinder surface.

The hydro test results are recorded and stamped on the cylinder along with the date of testing and the identification number of the authorized testing facility. The DOT requires that hydrostatic retesting and re-qualification be conducted by registered agents who have been certified by the DOT and who have been issued a valid Re-testers Identification Number (RIN) by the DOT Research and Special Programs Administration (RSPA). Hydro testing ensures that gas cylinders are safe and reliable for their intended use.

Post time: Oct-09-2023